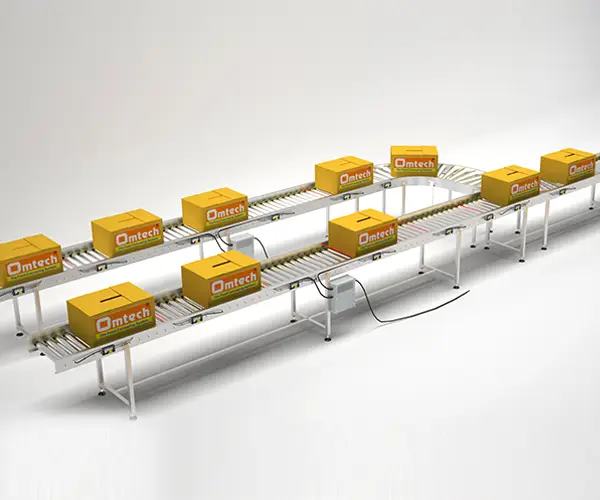

Conveyor systems are used to accumulate products, that is to prevent them from moving with the conveyor, establish a queue, and for a smooth material handling movement between upstream and downstream functions. However conventional systems allow products to collide with each other and pile up as the system stops. These are the causes of product damage as they increase pressure between products. Additionally, in conventional systems, the transmission medium continues to run constantly even when the products are immobile, which creates needless abrasion and wear and reduces efficiency. Thus, to prevent these rising issues we provide a zero-pressure accumulation roller conveyor system which is the solution to these problems.

Accumulation conveyor systems use a mixture of conveying mediums, including belts, rollers, or chains. Zero-pressure accumulation roller conveyors are a sequence of rollers carried in a border where objects can be moved either physically, by power, or by gravity. Zero-pressure accumulation roller conveyor systems in manufacturing or distribution units assist in conveying and mounting materials so they scientifically and systematically provide various processes such as wrapping, strapping, sorting, palletizing, etc.

This zero-pressure accumulation conveyor allows flexibility without any expensive mechanical services. And it also reduces the time consumed for installation and maintenance expenses.